Business model

The KION Group’s business model is designed so that customers of all sizes and from all kinds of industries can obtain the full spectrum of material handling products and services from a single source. Thanks to its broad technology base, diversified product portfolio and worldwide service network, the KION Group has the most comprehensive portfolio of such products and services in the market.

The KION Group divides its business into two segments for management purposes: Industrial Trucks & Services, which covers activities relating to industrial trucks plus supporting financial services, and Supply Chain Solutions, which focuses on intelligent supply chain and automation solutions. The two segments of the KION Group complement each other as they each have a strong market position and regional presence, which opens up opportunities for increasing revenue. The Supply Chain Solutions segment makes use of the service network and the reputation of the brands of the industrial truck business in key markets such as Europe, China and Brazil, while the Industrial Trucks & Services segment benefits from the strong standing of the supply chain solutions business in the US and European automation markets. Aligning the products and services with customers’ requirements will be a focus project within the Group’s strategy in the years ahead, culminating in an integrated, customer-centric KION Group business model.

Industrial Trucks & Services segment

So that it can fully cater to the needs of material handling customers worldwide, the business model of the Industrial Trucks & Services segment covers key steps of the value chain: product development, manufacturing, sales and logistics, spare parts business, truck rental and used trucks, fleet management and financial services that support the core industrial truck business. The segment operates a multi-brand strategy involving the three international brands Linde, STILL and Baoli plus the three national brands Fenwick, OM STILL and Voltas.

The segment earns a good half of its revenue by selling industrial trucks. The product portfolio includes counterbalance trucks powered by an electric drive or internal combustion engine, warehouse trucks (ride-on and hand-operated) and towing vehicles for industrial applications. It covers all load capacities, from one to 18 tonnes. Worldwide research and development activities (R&D) enable the Industrial Trucks & Services segment to consolidate its technology leadership, which it is extending in the areas of innovative, energy-efficient and low-emission drive technologies and hydrostatic and diesel-electric drive systems. In this field, the KION Group operates a total of 15 production facilities for industrial trucks and components in eight countries. Production got under way at the new factory in Stříbro, which is near Plzeň in the Czech Republic, during the year under review. So that it can ensure security of supply and the availability of spare parts for important components in order to meet customers’ specific requirements, the segment manufactures major components itself – notably lift masts, axles, counterweights and safety equipment. Other components – such as hydraulic components, electronic components, rechargeable batteries, engine components and industrial tyres – are purchased through the global procurement organisation.

As a rule, industrial trucks are built according to the customer’s individual specifications. Advantages for customers in terms of total cost of ownership (TCO) underpin the international Linde and STILL brands’ premium positioning. The trucks’ hallmarks are cost-efficiency, high productivity and high residual values. The international Baoli brand serves the lower end of the volume segment and the economy segment.

The segment is underpinned by an extensive sales and service network comprising around 1,400 outlets in over 100 countries and staffed by approximately 16,000 service employees. Around half of them are employed by the KION Group. In other cases, the operating units rely on external dealers.

The worldwide vehicle fleet, which comprised more than 1.2 million industrial trucks at the end of 2016, provides a stable basis for the spare parts, maintenance and repair business. The service business, which includes financial services, helps to smooth out fluctuations in the segment’s revenue and reduces dependency on market cycles. This business also strengthens customer relationships, thereby helping to generate sales of new trucks. Extensive supplementary services are offered, mainly for premium products. However, the proportion of service business is continually increasing in the other price segments too.

There are also individual orders for repairs and maintenance work as well as for spare parts. In addition, the segment looks after entire customer fleets, using special software to monitor the trucks in the fleets and to enable customers to efficiently manage their fleets.

The operating units also have extensive used truck and rental truck businesses, allowing peaks in capacity requirements to be met and customers to be supported after their leases have expired.

Financial services support new truck business in many markets, forming another pillar of the service business. About half of all new trucks are financed via the KION Group itself or via external banks and dealers. Offering financial services is therefore part of the truck sales process, and end customer finance is generally linked to a service contract throughout the term of the finance agreement. In the main sales markets with a high volume of financing and leasing, financial activities are handled by legally independent financial services companies. These activities include long-term leasing to customers and internal financing of the operating units’ short-term rental fleets.

Supply Chain Solutions segment

The Supply Chain Solutions segment, with its Dematic operating unit, is a strategic partner to customers in a variety of industries, supplying them with integrated technology and software solutions with which to optimise their supply chains. Manual and automated solutions are provided for all functions along customers’ supply chains, from goods inward and multishuttle warehouse systems to picking and automated palletising. Picking equipment controlled by radio, voice or light is available for nearly all goods and packaging types, whether it is used for case, individual item, split-case or pallet picking. Automated storage and retrieval systems (ASRS) such as RapidStore and high-performance picking stations (RapidPick) can be used to achieve very fast throughput times and picking rates. At the same time, cross-docking solutions increase the efficiency of the system as a whole by eliminating the unnecessary handling and storage of goods.

Real-time management of the supply chain solutions is based on the proprietary, open software platform Dematic iQ, which can be easily integrated into customers’ existing application landscape. Dematic iQ offers much more than traditional warehouse management systems, helping with the data-based optimisation of all processes to ensure seamless order processing. It also supports performance management functions for measuring and controlling performance.

Through its Dematic, Egemin Automation and Retrotech brand companies, this segment is primarily involved in customer-specific, longer-term project business. With global resources, ten production facilities worldwide and regional teams of experts, Dematic is able to plan and deliver logistics solutions with varying degrees of complexity anywhere in the world.

The (new) project business (business solutions) covers every phase of a new installation: analysis of the customer’s needs and the general parameters, provision of appropriate advice, computer simulation of bespoke intralogistics solutions in the customer’s individual environment, technical planning and design of the system, implementation of the control technology and its integration into the customer’s existing IT infrastructure, site and project management, plant monitoring and support for the customer during implementation of the system, including training for the workforce.

The system components, which are specified in detail for each customer project, such as automatic guided vehicles, palletisers, storage and picking equipment including automated storage and retrieval systems, sorters and conveyors, are manufactured inhouse at ten production facilities or, in some cases, by quality-assured third parties.

The breadth of this offering allows the segment to offer a one-stop shop for modernisation work and services (customer solutions), which usually cover the entire lifetime of an installation. The installed base of 6,000 or so systems provides significant potential for this business, including on-site support provided by approximately 1,700 employees in around 30 countries.

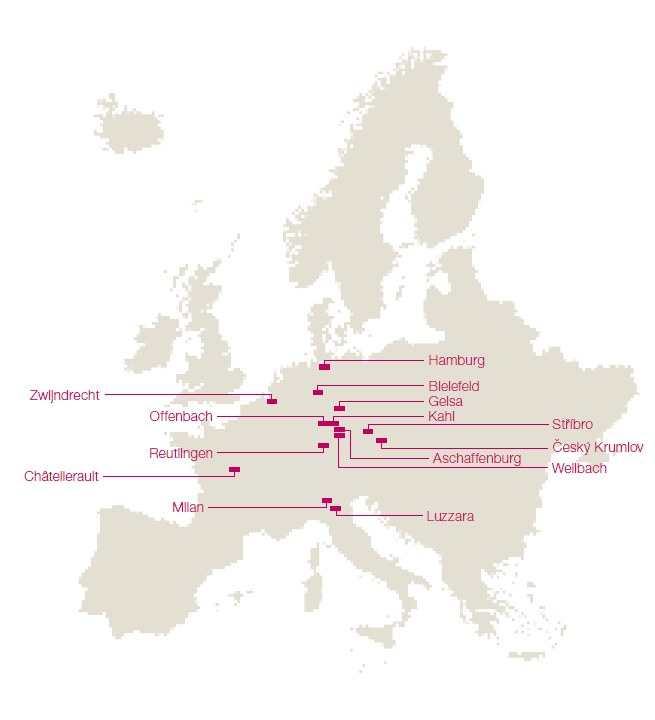

Production sites of the KION Group |

|

DIAGRAM 003 |

Industrial Trucks & Services |

||

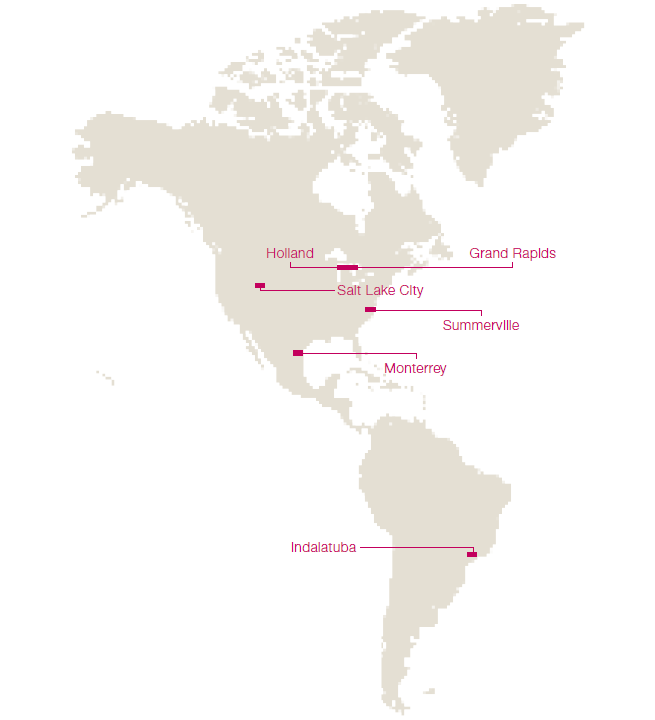

Brazil |

||

Indaiatuba / São Paulo: Counterbalance trucks with IC engine, warehouse technology |

||

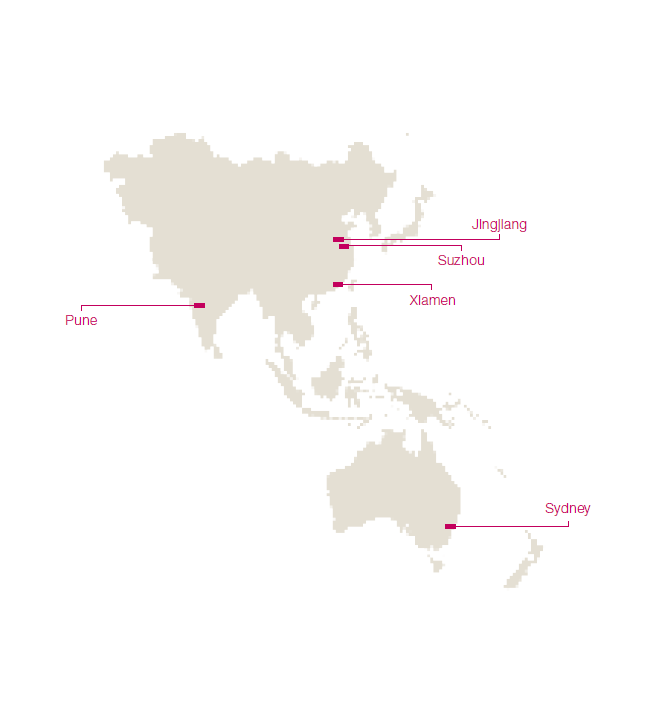

China |

||

Jingjiang: Counterbalance trucks with electric drive or IC engine, warehouse technology |

||

Xiamen: Counterbalance trucks with electric drive or IC engine, heavy trucks, warehouse technology |

||

Germany |

||

Aschaffenburg: Counterbalance trucks with electric drive or IC engine, warehouse technology |

||

Geisa: Component production |

||

Hamburg: Counterbalance trucks with electric drive or IC engine, warehouse technology, components |

||

Kahl: Spare parts warehouse, component production |

||

Reutlingen: Very narrow aisle trucks |

||

Weilbach: Component production |

||

France |

||

Châtellerault: Warehouse technology |

||

India |

||

Pune: Counterbalance trucks with electric drive or IC engine, warehouse technology |

||

Italy |

||

Luzzara: Warehouse technology |

||

Czech Republic |

||

Český Krumlov: Component production |

||

Stříbro: Warehouse technology |

||

United States |

||

Summerville: Counterbalance trucks with electric drive or IC engine, warehouse technology |

||

Supply Chain Solutions |

||

Australia |

||

Sydney: Conveyors and sorters, storage and retrieval systems, picking systems, automated guided vehicle systems, system components, mainly racking |

||

Belgium |

||

Zwijndrecht: Automated guided vehicle systems |

||

China |

||

Suzhou: Conveyors and sorters, storage and retrieval systems, picking systems |

||

Germany |

||

Bielefeld: Conveyors and sorters |

||

Offenbach: Conveyors and sorters, storage and retrieval systems, picking systems |

||

Italy |

||

Milan: Conveyors and sorters |

||

Mexico |

||

Monterrey: Conveyors and sorters, storage and retrieval systems, picking systems |

||

United States |

||

Grand Rapids: Conveyors and sorters, system components, mainly for loading trailers |

||

Holland: Automated guided vehicle systems |

||

Salt Lake City: Conveyors and sorters, storage and retrieval systems, picking systems, automated guided vehicle systems, system components, mainly RapidPick |