Potential.

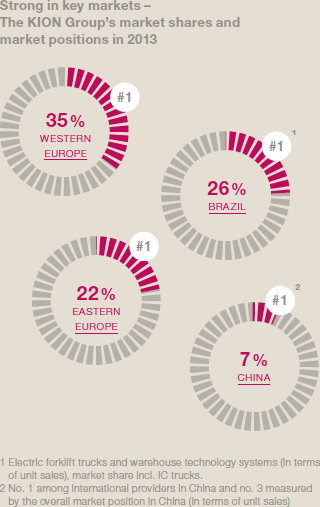

Around 530 forklift trucks were sold 2013 per million people in western Europe. In India it was just a handful – but that’s about to change. Through the Voltas brand company, the KION Group has made early inroads on the subcontinent, just as it did in China. India is ready and so is Anup Ramachandra Kurup.

Anup’s masterpiece weighs a good four tonnes. It’s painted yellow and grey, has a muscular appearance and is as good as impossible to knock over. The EVX 30 Max is the new forklift truck from Voltas Material Handling (VMH), the KION Group’s Indian brand company. “We took just four months to develop it,” says Anup Ramachandra Kurup, a senior engineer at VMH at the age of just thirty-two.

Anyone who visits Anup will quickly realise that big changes are under way here in the Indian city of Pune. The engineer and his colleagues are operating from a bare-looking office on the second floor, right above the production hall. Some 200 people here make around 2,000 forklift trucks a year. The factory is bursting at the seams. “We have big plans for VMH,” says Sunil K Gupta, head of what is still only the second biggest manufacturer of forklift trucks in India. “Our goal is clear: we want to be number one in this growth market.”

Anup and his colleagues work tirelessly to achieve this, often working above and beyond the call of duty. “Just before a product launch, it’s not unknown for us to pull an all-nighter,” says Anup. “But I don’t mind, because since we’ve really been working flat out, everything has been much more fun.”

“Delighted that the KION Group is on board”

Anup is well placed to compare the old times with the new. The man from the southern state of Kerala has been at VMH since 2008. At that time VMH was still based in the economic hub of Mumbai and was part of the vast Tata Group. No one in India’s biggest industrial conglomerate was paying proper attention to the relatively small forklift truck business, however. “When it was sold to the KION Group in 2011, we were over the moon. We’re now proud to be part of a globally operating group that is focused entirely on forklift trucks.”

Things moved very quickly: in summer 2012 VMH moved to the industrial city of Pune, where, as a stop-gap solution, it is leasing production halls. But Indians are well versed in improvisation and he and his colleagues are comfortable dealing with their temporary surroundings. His colleagues have even built themselves a small test track in the yard, complete with weights for the trucks to lift and inclines.

Synergies help to save huge amounts of time

The rate at which products are developed in Pune shows how dramatic the changes have been: “Previously we needed one year to design a new truck. We’ve since got it down to under four months.” It helps enormously that the developers are now able to draw on a whole raft of modules thanks to the takeover by the KION Group: “For the EVX 30 Max we used transmissions and axles from our sister brand Baoli in China. That saved a huge amount of time.”

To drive forward development, Anup constantly flits between his office with its large computer and the ‘proto shop’. Down here the prototypes designed by the engineers are constructed and put through their paces. There’s a strong smell of oil, spanners clang against metal and only the humming of the trucks’ engines drowns out the thud of hammers – a paradise for the engineer. At the edge of this workshop for new developments, which is out of bounds to visitors, stands the DVX 30 KAT. Another of Anup’s favourites: “It took half a year for our team to develop that truck,” he says. “Before starting, even we didn’t believe we could get a machine like that up and running in such a short space of time. But we managed it.” With the newly developed EVX 20 Max and EVX 30 Max, he and his team was even faster. What our young engineer doesn’t say: that he was named ‘employee of the year’ for this achievement.